When it comes to pipe repair and installation, the word eco-friendly isn’t the first thing to come to mind. But with the advancement of new techniques, like trenchless repair, the process is becoming more environmentally-friendly.

Epoxy lining, which is used in pipe rehabilitation, is an eco-friendly option for pipe repair.

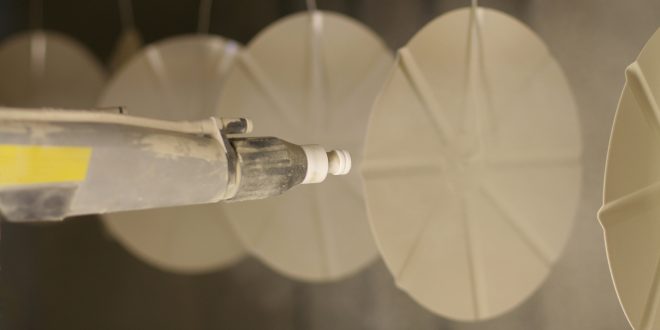

The lining is inserted into the interior of an existing, damaged pipe and is left to cure. After cured, the lining essentially creates a new pipe within the old pipe. A camera inspection is typically performed before the lining is inserted to pinpoint the location of the damage.

No Carbon Emissions

The manufacturing of epoxy liners and coatings does not produce carbon emissions. This means that the creation of these products does not contribute to greenhouse gases that trap heat inside of the earth’s atmosphere.

The environmentally-friendly manufacturing process alone makes epoxy lining a good option for those who are concerned about their environmental impact.

No Waste

In addition to not producing carbon emissions, the manufacturing of epoxy linings and coatings does not create any waste that needs to be transported to a landfill or recycled.

As Nu Flow explains, the existing pipe is left in place. Instead of removing the pipe, an epoxy liner is inserted into the existing pipe. The lining is left to be cured, or the technician will blow an epoxy coating through to seal pinhole leaks.

Prevents Heavy Metal Leaching

The use of epoxy liners helps prevent heavy metal leaching. When metal pipes start to corrode, heavy metals, like copper and lead, can leach into the water supply.

Epoxy coatings and linings are designed to prevent chemical leaching by covering the interior of the pipe to prevent water from touching the metal.

Heavy metals can wind up in nearby groundwater, which can contaminate drinking water and nearby wildlife and vegetation. Heavy metals in drinking water can have adverse health effects.

Prevents Breaks and Leaks

When epoxy liners are inserted into pipes and left to cure, they essentially create a new pipe. The lining fills in holes and damage in the existing pipe to prevent leaks and pipe breaks.

This allows users to enjoy clean drinking water and keep the pipes functioning properly for decades to come.

Conserves Water

When pipes leak or break, buildings waste water. Water-using appliances, sinks, showers and toilets will waste water when pipes are not working optimally. In fact, appliances alone waste trillions of gallons of water each year in the United States, according to the EPA.

Along with preventing heavy metal leaching and breaks in the pipe, epoxy linings conserve water supplies by preventing leaks and wasted water. The linings fill in damaged areas of the pipe that allow water to leak through to nearby groundwater.

Of course, the key most important thing is to ensure that the epoxy lining is installed properly and evenly. When not applied properly or evenly, the lining will do little to repair the problem and may even have a harder environmental impact than the damaged pipe itself.